Winter isn’t just tough on your roof, pipes, or heating system – it can also take a toll on your home’s electrical wiring. As the temperature drops and moisture levels rise, metal components in your electrical system become more vulnerable to corrosion.

Condensation from cold snaps, sudden temperature swings, and damp indoor air all create the perfect conditions for rust and deterioration on outlets, fixings, and connection points.

Why does this matter for your household? Corrosion doesn’t just make hardware look worn – it can weaken the reliability of your electrical connections.

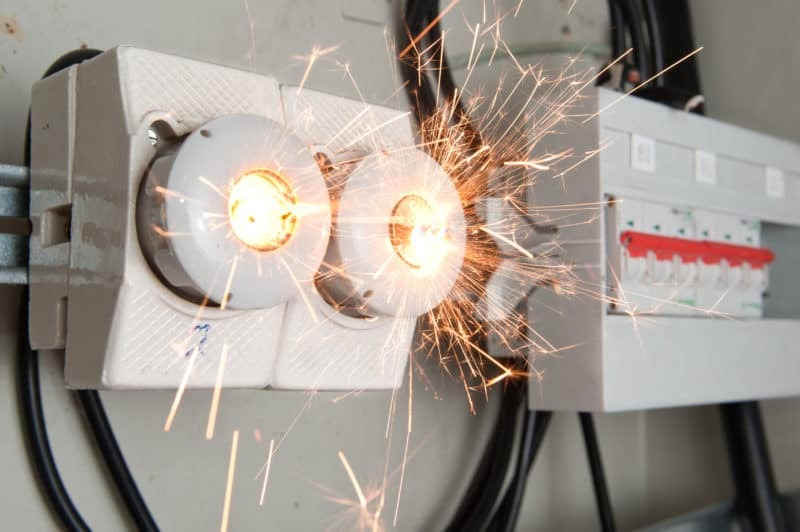

Poor connections lead to increased resistance, overheating, and in some cases, complete failures.

And if that happens during winter, when your family is relying on electricity for heating, lighting, and appliances, the impact can be both costly and inconvenient.

Why Winter Accelerates Electrical Corrosion Problems

When cold weather sets in, electrical systems face a faster rate of corrosion. The main culprit is condensation: when cold metal components meet warmer, humid air, moisture forms on the surface.

This thin film of water acts like an electrolyte, creating the perfect conditions for corrosion to take hold. Once moisture penetrates connectors, it accelerates degradation, which is why winter is a critical time for inspections and preventative maintenance.

Some of the key ways winter speeds up corrosion are:

- Condensation on cold surfaces – forms electrolytes that promote rapid metal breakdown.

- Moisture intrusion in connectors – accelerates degradation and weakens protective barriers.

- Salt exposure from gritted roads – creates highly conductive solutions that creep into junction boxes and fixings.

- De-icing chemicals – compounds like calcium magnesium chloride speed up wiring deterioration.

Road salt adds another layer of risk. Once dissolved, it produces a highly conductive solution that attacks exposed metal.

This salty mix can:

- Creep into junction boxes.

- Spread across connection points.

- Settle around fixing threads, undermining protective coatings.

Contractors commonly notice a higher number of corrosion-related faults just as winter moves forward. UK-wide, this trend becomes more pronounced where wet weather and widespread salt use combine.

Box fixings, earthing bolts, and cable supports often require the first attention once these harsh conditions appear. Keeping these fastening points performing well protects more than just hardware.

Key Fastening Points Requiring Winter Protection

Some parts of your home’s electrical system are more exposed to moisture and cold than others. Pay extra attention to these areas:

- Junction boxes and cable supports – Fluctuating temperatures cause expansion and contraction, which can loosen fixings and allow water inside.

- Outdoor lighting brackets and security fixtures -Rain, frost, and road salt speed up rust, especially where different metals touch, weakening both safety and structure.

- Meter boxes and consumer unit supports – Corrosion here threatens the stability of main supply equipment, making early checks essential.

By spotting rust or loose fixings early, you’ll prevent water intrusion, maintain weatherproof seals, and keep your system safe through the harsher months.

Identifying High-Risk Installation Areas

Coastal sites naturally stand out for their salt content, yet high winds can carry corrosive particles far inland, affecting rural or urban projects alike. Coastal regions require stronger protective measures such as dielectric grease and heat shrink tubing. Conventional stainless or galvanised fixings sometimes last just a season under harsh salt exposure.

Industrial facilities, such as food production and agricultural buildings, present a separate set of issues. Persistent damp and airborne chemicals interact with metal fixings, speeding up corrosion beyond what outdoor exposure alone produces.

Cattle sheds, for instance, present a combination of ammonia and humidity that wears down fixings rapidly.

Underground and basement installations are easily overlooked, but their combination of cold walls, minimal airflow, and ever-present damp leaves metal fixtures vulnerable if the wrong types are used. In these settings, standard precautions often fall short and a more resilient approach to both material specification and sealing becomes necessary.

Material Selection for Winter-Resistant Electrical Installations

Selecting the right stainless steel fixings is important for winter electrical work. A2 stainless steel works well for projects in most towns and rural areas, as it resists rust in normal weather. For jobs near the coast or where there is lots of road salt, A4 stainless steel is a better choice.

A4 holds up to salt and moisture much longer, which helps prevent rust in harsh winter conditions.

For reliable protection in harsh environments, Fixabolt supplies fixings that maintain their integrity through challenging winter conditions.

Galvanised options, particularly hot-dipped, are sometimes suitable for lower-risk or temporary work. Yet, frequent wetting and salt exposure near roads or parking areas quickly diminish their suitability, demanding more durable solutions. Keeping different metals apart also makes a difference.

Nylon or rubber washers break the electrical link between dissimilar metals, guarding against the galvanic action that causes faster decay at the fixing point.

Installation Techniques for Winter Durability

The way electrical components are installed makes a big difference in how well they stand up to cold and damp conditions. A few smart techniques can go a long way toward preventing corrosion and keeping your system safe:

- Tighten connections properly – Using the right pressure when fastening ensures joints are secure, gaskets fit snugly, and there’s no easy path for water to seep in.

- Use protective compounds – Thread-locking products not only stop screws from loosening but also help block out moisture.

- Add protective coatings – Anti-corrosion sprays or sealants provide an extra layer of defense in damp or exposed areas.

- Seal vulnerable points – Wrapping junctions with self-fusing tape or heat-shrink tubing keeps out both moisture and dirt.

- Choose quality hardware – Durable fixings designed for outdoor use give your installation the strength to last through harsh winter conditions.

Taking these steps during installation means fewer problems later – and peace of mind knowing your home’s electrical system is built to withstand the season.

Quality fixings from suppliers like Fixabolt provide the foundation for installations that withstand winter’s challenges.

Maintenance Schedule Recommendations

Monthly visual checks, focused on outdoor and damp-prone fastenings, allow prompt detection of early corrosion, from slight discolouration through to powdery growth at thread or nut boundaries.

Contractors document each finding, intervening with cleaning or re-coating as needed. Every quarter, systematic tightening and touch-up work provide an extra buffer.

Some installations facing persistently harsh conditions or high salt exposure benefit from scheduling annual replacement of selected fixings instead of expecting them to last another season.

Keeping a detailed log of inspections, interventions, and replacements allows contractors to spot patterns and adjust their approach, eliminating repeated failures in difficult locations before they happen.

Regulatory Compliance and Liability Considerations

Requirements under BS 7671 demand that fixings suit their anticipated environment and offer good durability. Increasingly, inspectors review fixings as part of their periodic checks, which means contractors show compliance not only through correct installation but also by maintaining accurate records on materials, installation dates, and any post-installation actions taken.

Careful documentation offers practical protection in the event of a fault or insurance enquiry. Contractors who record specification, sourcing, installation, and follow-up maintenance establish a visible commitment to quality and safety, helping to avoid both regulatory penalties and insurance claim disputes. Close attention to all these details helps keep systems running without unexpected downtime.