From kitchen makeovers to full-home storage solutions, custom cabinetry and built-in wardrobes are high on nearly every client’s list. These projects demand clean lines, personalized layouts, and a flawless finish—even when budgets and timelines are tight.

While demand is rising, many shops are still figuring out how to keep up efficiently. That’s where CNC technology steps in. Blue Elephant CNC, a leading furniture CNC machine manufacturer, offers modern solutions for shops focused on custom home projects like cabinets and wardrobes.

In this article, we’ll break down what makes a CNC setup work best for these types of jobs—so you can take on more work without making your process more complicated than it needs to be.

Cabinets vs. Wardrobes ─ Different Builds, Similar Needs

Cabinets and wardrobes may serve different functions in a home, but on the production floor, they share a surprising number of needs. Both rely on consistent panel processing, clean joinery, and accurate hole placement for hinges, handles, or shelving.

That said, the two builds do have their quirks.

Cabinets—especially kitchen or bathroom varieties—often require more pocket cuts and precise drilling for adjustable shelves, drawer slides, and euro hinges. You might also be working with tighter dimensions and more compact components.

Wardrobes, particularly custom full-height builds for closets or dressing rooms, often demand longer vertical panels, accommodations for sliding or mirrored doors, and occasionally thicker backing for structural support. Larger parts require more stable handling and may push the limits of your machine bed if you’re working with a smaller format.

The takeaway? If you’re working on both product types—or planning to—your furniture CNC workflow needs to be flexible without slowing you down.

Core Components of a Furniture CNC Setup for Cabinet and Wardrobe Work

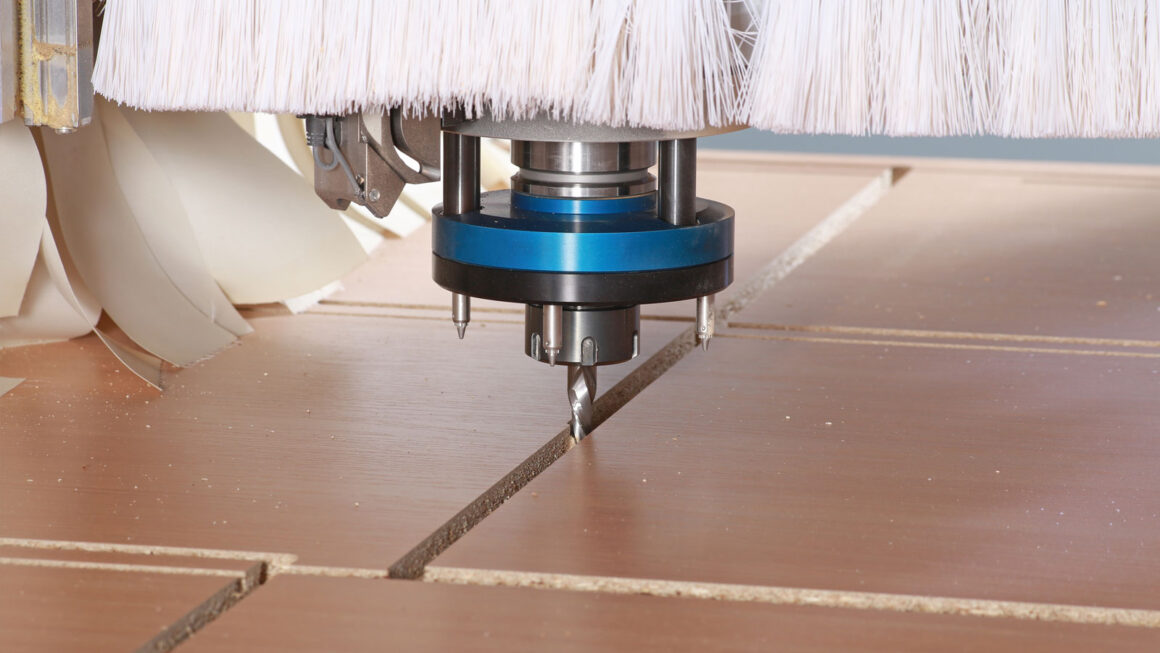

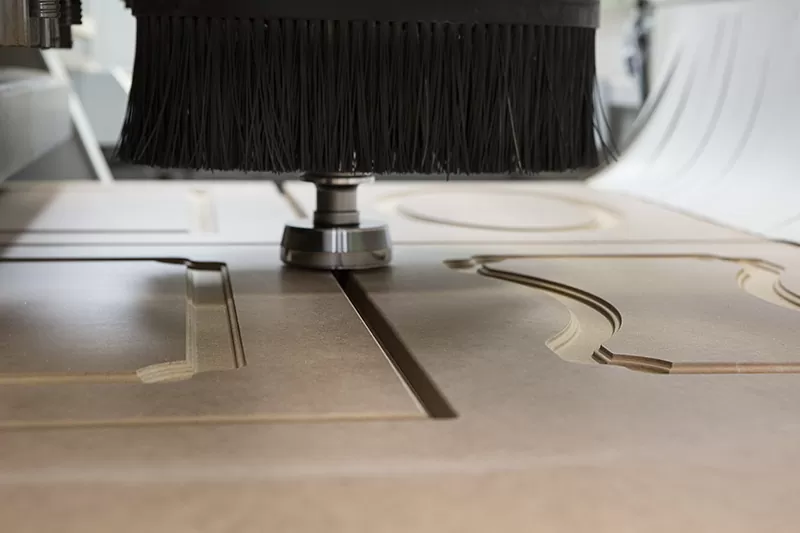

At the heart of any good setup is a nesting CNC router—the go-to choice for shops cutting sheet goods like MDF, plywood, or melamine. Nesting machines maximize material use while reducing handling time, making them ideal for cabinet and wardrobe production.

Beyond the machine itself, here’s what else you need to get the most out of your investment:

- CAD/CAM software ─ This is where your designs meet the machine. Look for software that handles nesting, hardware placement, part labeling, and quick edits. Bonus points if it integrates with cabinet design tools or supports libraries for common furniture components.

- Vacuum hold-down table─ Stability is key when cutting large parts. A strong vacuum bed holds material in place and helps improve cut quality—especially important with oversized wardrobe panels.

- Dust collection system ─ CNC work generates a lot of debris. A reliable dust collector keeps your shop cleaner, protects your tools, and improves air quality.

- Automatic tool changer (ATC) ─ If you’re switching between drill bits, end mills, and profile cutters in a single job, an ATC can dramatically speed up production.

- Labeling and part management tools ─ These might seem minor, but clear part labeling saves a ton of time during assembly—especially on larger or more complex builds.

- Material loading/unloading tables ─ Not essential for every shop, but if you’re dealing with volume or larger panels, these can help streamline your flow and reduce physical strain.

Start with a setup that covers most of your current projects—about 80–90%—and make sure it has room to grow as your needs evolve.

Space and Workflow ─ Make the Machine Fit You

Not every furniture business is working out of a massive warehouse. Many cabinet and wardrobe specialists operate in smaller spaces—whether that’s a garage, a mobile setup, or a compact commercial unit.

The good news is, you don’t need a huge footprint to run an efficient furniture CNC setup.

- A 4×8 CNC router handles standard panel sizes and is enough for most home-focused cabinet and wardrobe jobs.

- A 5×10 machine gives you a little more breathing room—ideal if you want to run full-sheet nesting while prepping your next load or if you’re starting to branch into larger builds.

But size isn’t everything. You’ll want to think through your full workflow:

- Where are your sheets stored?

- How do parts move from the machine to assembly or finishing?

- Do you have enough room to stack cut pieces without damaging them?

Sometimes, a more compact, all-in-one solution actually improves speed and space efficiency. Blue Elephant’s lineup includes smart options for small-to-medium shops that prioritize layout and output.

Speed Meets Customization ─ CNC for the Real World

Older CNC setups were geared for mass production—run the same job, over and over, with minimal variation. That doesn’t fit modern home renovation and furniture work.

Today’s furniture CNC machines are built for speed plus flexibility.

Let’s say you’re cutting wardrobe side panels with shelf holes in the morning. In the afternoon, you’re routing shaker drawer fronts with raised profiles. A smart CNC setup makes that switch seamless, without hours of reprogramming or tool changes.

File tweaks are quick, too. That odd-sized closet? No problem. Just adjust the dimensions in your design software, and your machine’s ready to go.

This kind of responsiveness keeps clients happy, especially on remodeling projects where measurements can shift and timelines are tight.

Choosing the Right CNC Partner ─ Why It Matters

A good machine is a solid start—but without the right support, even the best equipment can fall short. When investing in a furniture CNC setup, think long-term. You’re not just buying hardware; you’re building a production system.

Here’s what to look for in a CNC partner:

- Training and onboarding for both software and hardware

- Responsive support, especially during the learning curve or busy seasons

- Furniture-focused configuration options to suit your specific workflow

- Scalable systems that grow with your business

Blue Elephant CNC is known for working directly with custom furniture shops, offering setup guidance and real-world-tested configurations that help reduce downtime and boost confidence from day one.

Final Thoughts ─ Build Smarter, Not Harder

If you’re building custom kitchens, closets, or whole-house storage, the right furniture CNC setup lets you scale your business without overloading your crew. Clean cuts, fewer mistakes, and repeatable designs mean you can take on more jobs and finish them faster—without sacrificing quality.

Take a look at your current workflow. Are you losing time in layout? Struggling with repeat accuracy? Dreading last-minute changes? That’s where CNC can make a big difference.

And with companies like Blue Elephant CNC offering tailored machines for cabinet and wardrobe work, the move to automation is easier than ever.