Decarboxylation machines are a versatile addition to any kitchen, offering benefits beyond herbal processing.

Whether you’re interested in creating homemade herbal remedies, elevating your cooking game with infused herbs and spices, or making your own edibles, a decarboxylation machine can simplify the process and enhance the end results.

One way to incorporate decarboxylated herbs into your daily routine is by creating your own homemade herbal remedies. With a decarboxylation machine, you can easily activate the ingredients in raw plant material, making it more effective in treating a variety of ailments.

Additionally, other herbs, such as chamomile and lavender, can be processed using a decarboxylation machine to create teas, tonics, and other remedies that promote relaxation, sleep, and overall well-being. If you’re a foodie, you may want to consider using a decarboxylation machine to infuse herbs into your culinary creations. Decarboxylated herbs have enhanced flavor and aroma, making them ideal for use in a variety of dishes.

Enhance Your Cooking

For example, you can use infused oils and butters to add flavor to roasted vegetables, pasta dishes, and sauces. You can also create your own spice blends and seasoning mixes using decarboxylated herbs, such as rosemary, thyme, and oregano, to add depth and complexity to your cooking. Finally, if you’re interested in making your own spices or edibles, a decarboxylation device is a must-have tool.

Factors to Consider When Choosing a Decarboxylation Machine

Capacity

One of the most important factors to consider when choosing a decarboxylation machine is capacity. Depending on your processing needs, you may require a machine that can handle a small or large volume of plant material. If you are processing on a small scale, a machine with a smaller capacity may be sufficient. However, if you plan to process large volumes of material, you may need a machine with a larger capacity to save time and increase efficiency.

Temperature Control

Temperature control is another critical factor to consider when choosing a decarboxylation machine. The decarboxylation process requires precise temperature control to ensure that the plants or spices are properly activated without being degraded. Look for a machine with accurate temperature control and the ability to maintain a consistent temperature throughout the process.

Types of Decarboxylation Machines

There are two main types of decarboxylation machines: oven decarboxylation machines and closed-loop decarboxylation machines.

Oven Decarboxylation Machines

Oven decarboxylation machines are the most common type of decarboxylation machine. They typically consist of a metal box with heating elements that heat the air inside the box. The plant material is spread out on trays inside the box, and the heated air circulates around the material to activate the plant matter.

Closed-Loop Decarboxylation Machines

Closed-loop decarboxylation machines are a newer type of machine that uses a vacuum and inert gas to maintain a precise and consistent environment for the decarboxylation process. These machines are more expensive than oven decarboxylation machines but offer greater precision and control over the process.

How to Choose the Right Decarboxylation Machine for Your Herbal Processing Needs

Consider Your Budget

Decarboxylation machines can range in price from a few hundred dollars to several thousand dollars. Consider your budget when choosing a machine, but also keep in mind that a higher price may come with additional features and greater precision.

Determine Your Volume Needs

Think about how much plant material you will be processing at once and how often you will be using the machine. This will help you determine the capacity you need and whether you need a more expensive closed-loop machine or a more affordable oven machine.

Look for Additional Features

Consider additional features that may be important to your processing needs. For example, some machines have a built-in timer to automate the process and ensure accuracy. Others may have adjustable shelves to accommodate different sizes of plant material. Look for a machine with the features that will be most useful to you.

Processing Herbs with the Decarboxylation Machine

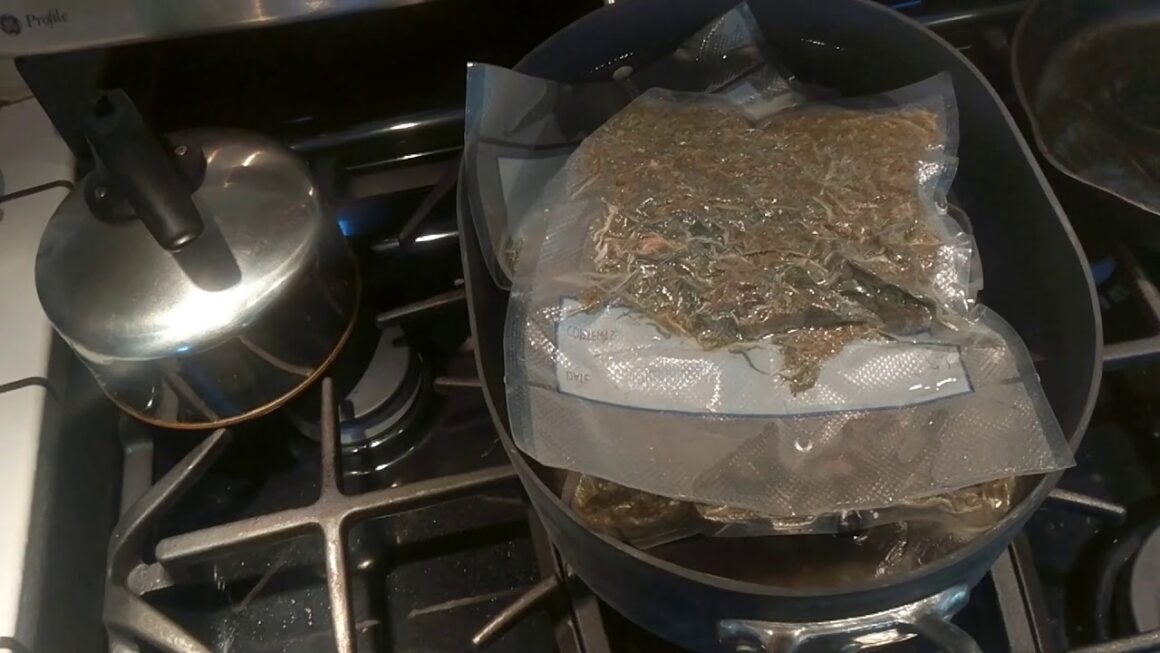

When processing herbs with a decarboxylation machine, it is important to follow these steps:

- Preheat the machine to the desired temperature.

- Grind the herbs into small pieces and spread it out evenly on the trays.

- Place the trays inside the machine and close the door.

- Set the timer and allow the machine to run for the desired amount of time.

Once the process is complete, remove the trays and allow the herbs to cool before further processing or use.

Choosing the right decarboxylation machine is essential for efficient and accurate herbal processing. Consider the capacity, temperature control, and additional features when selecting a machine. Remember that closed-loop machines offer greater precision but come with a higher price tag. And when processing herbs, be sure to follow the proper steps to ensure the best results. With the right machine and process, you can achieve high-quality herbal products with ease.